[ 190411 Doug, I just added links to offsite products that would be advisable for people to use around CNC machines. As I wrote the one-liners, I saw myself as a Canadian who has seen friends suffering from this stuff. That could explain the canadian warnings in one of the thumbnails.SD ]

Machinists make the economy. Nobody adds more value than people who make things. By people who KNOW HOW to make things. It’s a fact that for every manufacturing job, almost TEN ordinary jobs are created.

Here’s a link to some gloves you can use for protection: https://www.grainger.com/product/ANSELL-9-1-2-Powder-Free-Unlined-1RL58

Here’s a link to a respirator that looks suitable for oily mist: https://www.grainger.com/product/3M-P95-Disposable-Respirator-4JG30

Here’s a couple of hand cleaners that aren’t bad for your skin: https://www.grainger.com/product/WORX-ALL-NATURAL-HAND-CLEANER-Citrus-Liquid-Hand-Cleaner-49AY03

and the other one: https://www.grainger.com/product/ZEBRA-SKIMMERS-CORP-Lemon-Liquid-Hand-Soap-34WP49

Something for the shop that your boss might like to add. This first one collects mist so you don’t have to breath it into your lungs: https://www.reven.de/index.php It’s German, and one of the best ones I’ve ever seen. No moving parts, extremely effective.

This other product is from the States, and is the only one I’ve ever seen that can do it all. No more touching concentrate, that’s the worst! https://sumpsync.com

Not only is machining critical to the economy, but it’s a profession that few people can handle. You work with materials ordinary people can’t imagine. You cut using mind-blowing feeds and speeds. Chips are like knives and needles, and you make them by the ton.

It’s also one of the most dangerous. If it’s not knife sharp chips, it’s jet-engine screams or heavy lift machines. And one of the least understood hazards is chemicals, like those of your coolant. Check out this story. These guys lost their jobs, and health, because of what they were breathing and touching.

Your metalworking fluids (MWF) are all around. They make cutting easier, they help the tools last longer, and they improve precision and surface finish.

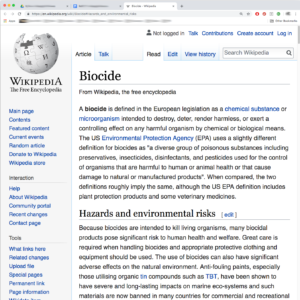

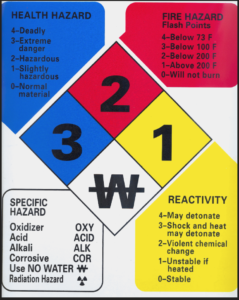

But they also penetrate your skin. You’re breathing it. You’re getting it on your hands. And in its concentrated form, you’re exposing yourself to biocides. All bad stuff.

But they also penetrate your skin. You’re breathing it. You’re getting it on your hands. And in its concentrated form, you’re exposing yourself to biocides. All bad stuff.

Look, we may not be able to save you from the chips, the noise, or many of the physical dangers that surround you as a machinist. But we are experts on the cutting fluid side of things, and as far as the MWF goes, Zebra can help you out.

We’re selling the TBD5, the latest in Dazzle technology from Zebra. This device keeps you as far away from the biocide filled concentrate as possible.

First of all, you only have to deal with the concentrate once every two weeks, not every day. Second, you never have to worry about mixing it with the coolant. We do that for you. Third, you don’t have to worry about sticking your head into the bowels of the machine in order to figure out how much fluid needs to be added. We also do that for you.

The concentrate is the most dangerous form that your MWF takes, and we keep you as far away as possible. After all, those chemicals penetrate your skin within seconds. And who knows the long-term effects?

That said, it’s also super-easy to install. All you have to do is place the Controller and Pail near your machine. Install the sump level sensor, fill the pail with concentrate (be careful!), and hook up the water supply. Batteries are included, so you’re done. Stand back and let the TBD5 do all your dirty work. So you can get on with what’s truly important.

What’s our experience with this? Lots. We’ve been developing and installing these at the system level for decades. Our customers include Mazak and Trumpf. No one has the technical chops or experience of Zebra. And now we’re putting it to use for smaller shops and individuals. Early devices cost $20k. Then we developed another series that cost $2k.

For a short time only, you can get your TBD5 for only $200. That’s 1/100 of the price that it cost 10 years ago. If you act now, you’ll not only get a money-back guarantee, but also other offers to be announced in the near future. But you’ll have to hurry, because we’re only offering these special offers to a select few. Apply now using this form.

Finally, you probably have to bring this to the attention of purchasing, production, or other management. Here’s a helpful sheet that you might think about printing out and handing them. It should prove to them why our product makes sense for them as well. It saves the company time and money, giving you more time to focus on quality and production.

Thanks for reading. Here’s more stuff that proves how bad these things are for you. Call us now.